Programmable 3D Printers Creating New Epiphyseal Growth Plate Cartilage As Interchangeable Body Parts

Note: This will be the last of a series of really long posts I have been writing for this past month. I realize that some of the post I did this month have been extremely long. I need to personally take a break away from the insane speed of writing I’ve done for this website, and will give the research responsibilities to Tyler for the next coming 2 months. The monthly reports will continue though. I am going to diverge a little away from the research when I come back in May since I wanted to expand a little on the subjects I wanted to add onto this website.

Note: This will be the last of a series of really long posts I have been writing for this past month. I realize that some of the post I did this month have been extremely long. I need to personally take a break away from the insane speed of writing I’ve done for this website, and will give the research responsibilities to Tyler for the next coming 2 months. The monthly reports will continue though. I am going to diverge a little away from the research when I come back in May since I wanted to expand a little on the subjects I wanted to add onto this website.

In a recently Youtube Video I watched where the Venture Capitalist Steve Jurvetson was being interviewed by entrepreneur Jason Calacanis, they started to get into talks about some of the companies that Jurvetson has invested in over the last 20 years. His vision is that in the next few decades, the biotech, nanotech, and IT fields will somehow start to merge into one multidisciplinary field which has full of potential for disruptive innovation and technologies. The idea that the field of biology, computer science, and the shrinking of the devices we can design suggest a few ideas which I wanted to propose to the readers of this blog. (I have put the video below)

(Note: I’ve been a huge fan of Steve Jurvetson for years now and after finding this recent article by Eliezer_Yudkowsky on Steve in the post “Competent Elites“ I think it is safe to say that he is one of those people which has a g factor that is far higher than most people in the world based on his academic pedigree. Interestingly, I somehow managed to get to that article from the blog Information Processing run by Stephen Hsu, who seems to enjoy talking about intelligence and the elitism associated with going to good universities. It is really interesting to read about the inner mechanics of what happens in the higher institutions of society. But that is a conversation for another day.)

Something that he did mentioned/reference in other videos I’ve seen him in, like in Google Talks and Entrepreneurship & Startup Business Conferences has been this seminal work entitled “The Law of Accelerating Returns” written by Ray Kurzweil back in 2001. I spent a full hour dissecting that particular piece of analysis to get a vague idea of how a person should understand the process of the growth of technology and innovation, and what might be expected in the coming decades.

It is really worth the time of the readers of this website to see what the Singularity University (or even the idea of the Technology Singularity) is all about. At the rate at which technology is completely overtaking almost all areas and aspects of our lives, there may come a point within the next century where the vast majority of people will no longer have jobs since they are completely done by robots which have intelligence and capabilities which far outstrip our own.

He also mentioned Kathleen Eisenhardt who is a Professor at the School of Engineering in Stanford University and also the annual retreat by Google called the Google X Retreat and Larry Page’s personal desire to beat death itself in starting Calico, which is supposed to do breakthrough research to help people increase their longevity.

So what does all of that have to do with what we are trying to figure out, which is a way to increase our height?

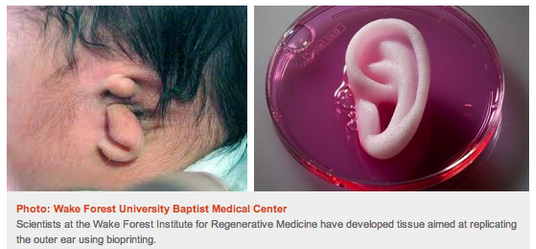

Well, there was some mention of the disruptive technology of 3D Printers. At some point before, I’ve written a short post on the possibility of using Electro-Spinning and growing cartilage tissue in a culture dish “Increase Height And Grow Taller Through Bioprinting And Electrospinning“. There was a famous picture I had on that post, of a fully regrown ear which I will post below. Ear is made from fibrocartilage. Fibrocartilage is not the same type of cartilage found in growth plates but it would not be that hard to make 3D models of other types of cartilage.

When I get back to the States, specifically Seattle in a few months, I am going to plan to look into the possibility of starting a small corporation to obtain laboratory equipment from the local University of Washington Surplus Store. Over time I am interested in buying a fully functioning 3-D Printer, and getting the neccessary tissue engineering cultures to print out unique batched of human tissue.

I want to personally try to run my own lab in house to test the viability of growing human tissue, specifically neural and chondrogenic tissue. I fully believe that with the right type of chemical compound like Thyroxine we can get the chondrocytes to be align properly, forming one of the key layers for growth plate formation, for easy implantation of cartilage tissue between bone segments.

I would like to refer to the article from Live Sciences “3D Printing Aims to Deliver Organs on Demand“. They talk about how the level of difficulty in reconstructing different types of tissue and organs can be divided into 4 groups.

- 1st Level (Easiest to build): Flat structures with mostly one type of cell, such as human skin, represent the easiest organs to make

- 2nd Level (Still somewhat easy): Tubular structures with two major cell types, such as blood vessels, pose a greater challenge

- 3rd Level (Medium in difficulty): Hollow organs such as the stomach or bladder, each with more complicated functions and interactions with other organs

- 4th Level (Extremely complex): Fourth level of complexity includes organs such as the heart, liver and kidneys — the ultimate goal for bioprinting pioneers

We briefly mentioned Anthony Atala (Director of the Wake Forest Institute for Regenerative Medicine in Winston-Salem, N.C) before in the last post about using 3D printers to be used for bio-printing and electro-spinning. He founded the company Tengion to look into the various ways to regenerate the types of tissues in the human body.

From the article….

- “Regenerative medicine has already implanted lab-grown skin, tracheas and bladders into patients — body parts grown slowly through a combination of artificial scaffolds and living human cells“

- “Atala’s group previously built lab-grown organs by creating artificial scaffolds in the shape of the desired organ and seeding the scaffold with living cells”

- “The ability to print full-size functioning organs depends on figuring out how to seed 3D-printed organs with both large and small blood vessels that can supply nutrient-rich blood to keep living tissue healthy. So far, no lab has succeeded in 3D-printing organs with the network of blood vessels necessary to sustain them.”

It is my belief that the entire structure and form of most growth plates would put the level of difficulty in creating such a cell in scaffold structure to be in just the 1st level of difficulty. Most growth plates are only about 2 cm thick, even among the youngest of children. That thickness can be modeled easily by a 3D bioprinter. The way that bio-printers work is from depositing layers and layers of cell culture/alginate/hydrogel/scaffold on top of each other, dispersing the live cells of various types evenly distributed over the previous layer.

After the cartilage layer has been created to be similar in shape & form to the normal cartilages, we would test the material strength and properties of the home-grown tissue. Over time, we will put it to structural tests over its tensile strength and compressive strength. It will have to be able to withstand

It is my hope that within 5 years, we would be able to test the idea on humans. I would personally put my own body to the test, wherein I would get one of my fingers to be fractured/cut and have the cartilage implanted to show that implantation of mass bio-printed growth plates would lead to the bones regrowing in length again in the natural process.

We refer to the person to read the following posts below which shows why this idea is completely valid…

- A Real Alternative To Limb Lengthening Surgery – Epiphyseal Growth Plate Regeneration, Regrowth, Implantation, And Transplantation Is Completely Possible (Big Breakthrough!)

- Bioengineering and Characterization of Physeal Transplant with Physeal Reconstruction Potential

- Engineering Growing Cartilage Tissue In Vivo Through Chondrocyte Transplantation (Big Breakthrough!)

- Engineering growing tissues (Authors: Eben Alsberg, Kenneth W. Anderson, Amru Albeiruti, Jon A. Rowley, and David J. Mooney)

- Histological Study of a Human Epiphyseal Transplant at 3 Years After Transplantion

- Epiphyseal transplant: harvesting technique of the proximal fibula based on the anterior tibial artery

- Free vascularized growth-plate transfer after bone tumor resection in children

From reading over the various groups of surgeons who already tried the physeal transplantation on children who might have had some type of tumor on the growth plate cartilage, after the excision of the tumor, they replaced the tissue area with the cartilage. The major problem has been on how do the surgeons get the implanted cartilage to become vascularized. Our biggest technical problem will most likely be on how do we make sure that the cartilage tissue that we print out gets the micro-blood vessels to run through the cartilage, which is supposed to be semi-anaerobic in nature. One group used something known as microsurgical anastomoses, which we havent’ done any research on yet.

Pingback: This Researcher Succeeded In 3D-Printing Spinal Discs Allowing Adults With Closed Growth Plates To Grow Taller If They Desired - Big Breakthrough